We’ve perfected the engineering processes when it comes to manufacturing our sealing screws. Our expertise in analyzing and selecting materials puts us at the top in our field. We’ve tested our sealing screws against aggressive substances and under extreme temperatures and pressures, and we’ve tested them with a plethora of various surface materials. Our engineers use special jigs and tools to design the ideal O-ring for each type of fastener. Our manufacturing processes meet Military standards and our sealing screws are DFARS & ROHS compliant. We use a combination of the following materials for the metal component of the screws: Stainless Steel (most common), Steel, Aluminum, Copper, Brass, Monel, Austenitic,and Titanium. Moreover, our clients customize everything–from threading to head shape to driver type, and even the materials themselves. There are a number of factors one needs to take into consideration when choosing the ideal sealing screw types for an application. Our engineers are always happy to sit down and work with you as you select the best materials for your individual product needs. Please refer to our Screw Material Guide when selecting options to complement your application and please contact ZAGO to receive personal consultation and to learn more about our sealing screws. ZAGO offers the following materials for the O-rings, which come in durometer ranges from 60-70 hardness depending on the chosen material: EPDM, Buna, Neoprene, Silicone, Fluorosiliconme, Viton, and Mil Spec O-ring materials. Other materials are available upon request. When choosing the best O-ring for your project there are several factors to consider: the specific application for which the O-ring is to be used, the size of the fastener to be sealed, the media type that needs to be sealed, and the temperature and pressure to which the O-ring must be subjected. After considering each one of these factors, the appropriate O-ring type is selected. Please refer to our O-Ring Material Guide when selecting the most suitable material for your O-ring and please contact ZAGO to receive personal consultation and to hear more about O-rings.

Fasteners

- Types: ZAGO manufactures many types of fasteners including screws, bolts, nuts, and socket caps with many varieties of heads and drives. In addition, ZAGO is capable of manufacturing both right-handed screws (screws tightened by being turned clockwise) and left-handed screws (screws tightened by being turned counter-clockwise).

- Drives: Available drives include Philips, Slotted, Combination Phillips/Slotted, Allen (a.k.a. socket), Hexagonal Recess, Square, 6 Lobe, Hex/Slotted Hex/Hex Flange, One Ways, and Socket Pin Heads Spanner.

- Head Recess Guidelines: Choosing the correct drive recess for an application can mean the difference between optimum productivity and down time. Often these decisions are only addressed when problems occur in the production line. ZAGO offers the above information to assist in the proper selection of driving recess for your seal screw application. For a difficult assembly application, we also offer assistance from our engineering department to help in resolving existing problems or to improve your product drive system.

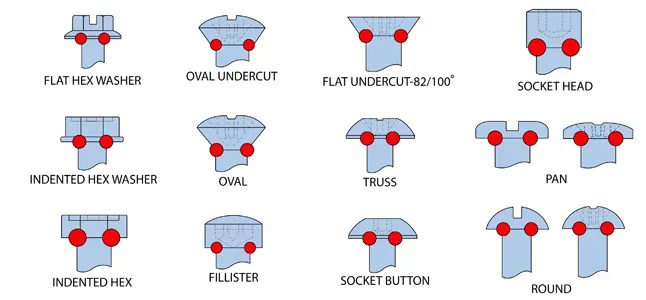

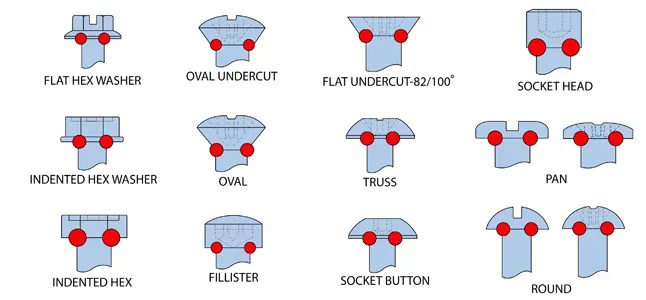

- Head Style: After you have chosen the correct recess system, you will next have to select the appropriate head style. ZAGO can supply all types of head styles including pan heads, flat heads, button heads, round heads, truss heads, oval or raised heads, bugle head, cheese head, fillister head, socket head and mirror head screws. ZAGO offers you the choice of military standard screws or other head style designs. Make sure to take into account all design factors, such as torque transfer stress in the fastener recess and the open diameter to be sealed. In addition, you may want to consider the availability and cost due to the fact that there are standard head styles for certain drive systems and that some head styles do not accept all recess systems.

- Material: ZAGO’s fasteners are available in a number of different materials. The most common material requested by ZAGO’s customers is stainless steel. Where great resistance to weather or corrosion is required, stainless steel, titanium, brass or bronze may be used, or a coating such as brass, zinc or black oxide applied. Click here for criteria for proper material selection and click here for detailed information on material components.

- Threading: ZAGO can supply its customers with all standard threading including Class 2A and will work with its customers to meet their specific threading needs. Non-standard lengths of threads and special threads such as left hand, metric and double lead threads are no problem for ZAGO to manufacture.