- Overview

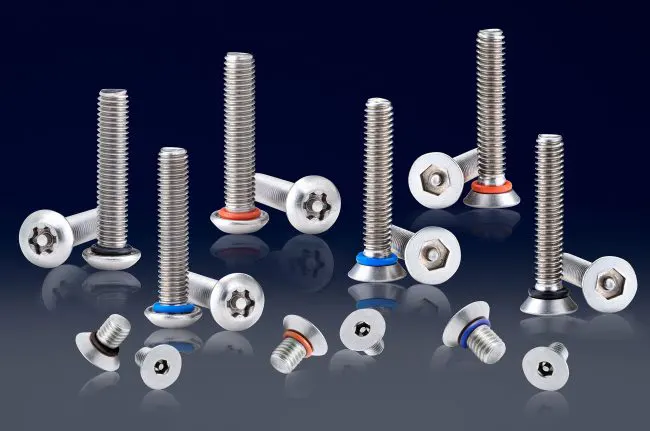

- What are Sealing Fasteners?

- What are Security Screws?

- Clearance Hole Data

- Dimensional Tables

- Installation and Torque

- Choosing Your Screw Material

- Choosing Your O-Ring Material

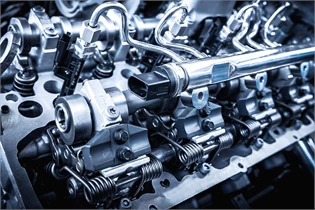

- Sealing Screws Engineering

- Sealing Screw or Sealant?

- Crystal Switch Seals Specifications

- Self-Sealing Nuts Engineering

- Switch Boots Engineering

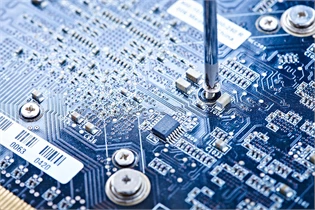

- IP-Rated Sealing Solutions

- Product Catalog (PDF)